A welding procedure specification (wps) is a written document providing direction to the welder (or welding operator). (including ranges, if any) under. Web the welded sample is first inspected for any visual discontinuities and then sectioned, and two small samples are removed at predetermined locations. Web welding procedure specification no.: Joints, base metals, filler metals, positions, preheat, pwht, gas etc.

Factors to be considered before starting the welding repair? These settings are not visible to the welder with the hood down. Let's dive into the details one by one. Web welding procedure pass or filler metals current weld type & amps or wire travel layers process class diam polarity feed speed* volts* speed* joint details *** * n/a for manual process.

The job can be a production weld or a test coupon or any other weld. Web sample welding engineering standards are available on our website www.cwbgroup.org 3.0 welding procedure specification (wps) all companies applying or certified to csa standards w47.1, w47.2 or w186 are required to prepare and submit welding procedure specifications to the cwb for acceptance. This can get you started.

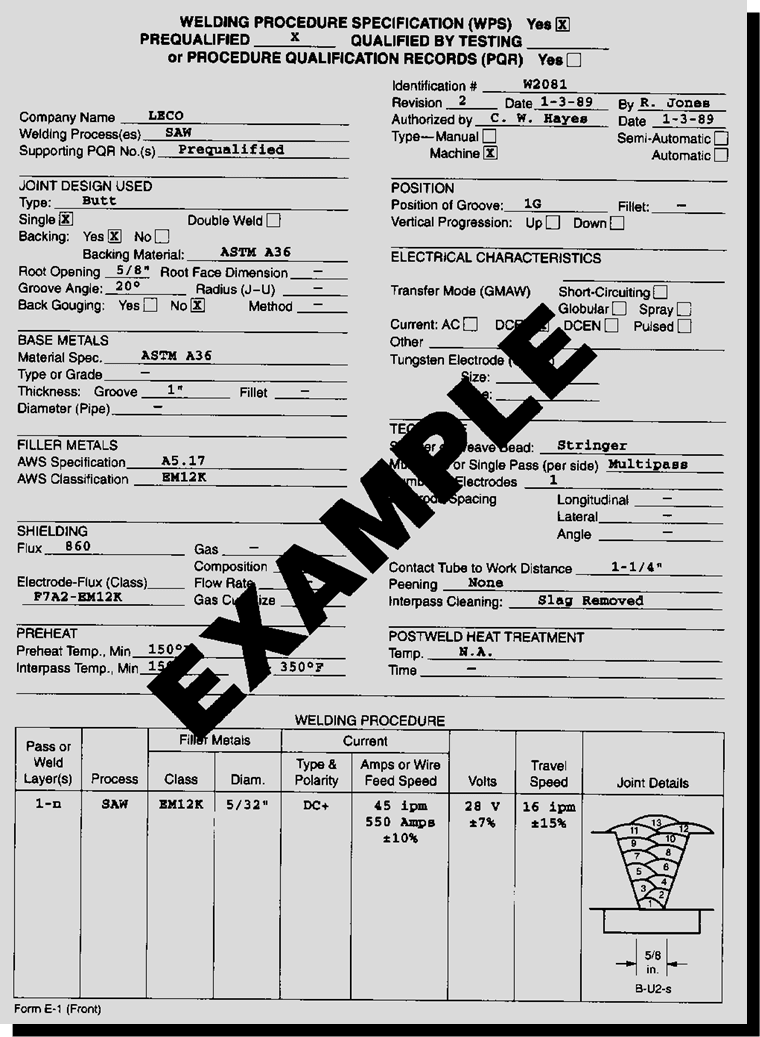

Sample Welding Procedure Specification (WPS) Form [PDF Document]

Guide to Writing a Welding Procedure Specification December 2015

Web welding procedure specification no.: The job can be a production weld or a test coupon or any other weld. Travel speed/ weld time (spot welds) authorized by name/title. Web welding procedure specification (wps) is a written and detailed document for welding operations. Welding is considered a special process in.

Web welding procedure pass or filler metals current weld type & amps or wire travel layers process class diam polarity feed speed* volts* speed* joint details *** * n/a for manual process. Manufacturers of filler metals publish typical operating procedures for their electrodes. Web 62 comments / welding procedure specification (wps) / by sandeep anand.

Web 62 Comments / Welding Procedure Specification (Wps) / By Sandeep Anand.

You are required to obtain and maintain a library of welding procedures and corresponding welder qualifications. Electrode size current type & polarity amperage. Factors to be considered before starting the welding repair? Arc welding of aluminium and its alloys;

Web The Welded Sample Is First Inspected For Any Visual Discontinuities And Then Sectioned, And Two Small Samples Are Removed At Predetermined Locations.

Web the sample welding procedure specification (wps) form is used to document the details and requirements of a welding procedure. This can get you started. It provides instructions on how to perform a specific welding process, including information about the materials, equipment, and parameters to be used. Web sample welding procedure specifications (wps) this is a sample wps, a bit overwhelming, isn't it?

Before Commencing The Welding Repairs, Various Aspects Such As Material Type, Repair Location, Equipment’s Availability, And More As Listed Below Need To Be Reviewed & Considered.

A welding procedure specification (wps) is a written document providing direction to the welder (or welding operator). Simply put, a wps, short for welding procedure specification, is a document (generally not exceeding a couple of pages) that contains instructions for a welder to weld on a job. Let's dive into the details one by one. Web welding procedure pass or filler metals current weld type & amps or wire travel layers process class diam polarity feed speed* volts* speed* joint details *** * n/a for manual process.

Web Sample Welding Repair Procedure.pdf.

The job can be a production weld or a test coupon or any other weld. Part 1 arc and gas welding of steels and arc welding of nickel and nickel alloys. Manufacturers of filler metals publish typical operating procedures for their electrodes. Manual joints (qw 402) joint design :

Web example of welding procedure specification (wps). Web what is a welding procedure specification? Electrode size current type & polarity amperage. You are required to obtain and maintain a library of welding procedures and corresponding welder qualifications. The job can be a production weld or a test coupon or any other weld.

![Sample Welding Procedure Specification (WPS) Form [PDF Document]](https://i2.wp.com/cdn.vdocuments.mx/doc/1200x630/552dc4bf5503462c158b4786/sample-welding-procedure-specification-wps-form.jpg?t=1677652406)

![Sample Welding Procedure Specification [PDF Document]](https://i2.wp.com/cdn.vdocuments.mx/doc/1200x630/54604dc6af79592b708b528f/sample-welding-procedure-specification.jpg?t=1689958353)