Web 62 comments / welding procedure specification (wps) / by sandeep anand. Electrode size current type & polarity amperage. X to xmm welders name: 27.05.2010 welding process (es) : Web (excerpt from aws b2.1/b2.1m:2021) the american welding society, acting under ansi rules for consensus standards, publishes aws standard welding procedure specifications (swpss) which are initiated by the b2g subcommittee on procedure qualification records.

Joints, base metals, filler metals, positions, preheat, pwht, gas etc. This document specifies requirements for the content of welding procedure specifications for arc welding processes. Pa (flat) joint design welding sequence welding details: Web sample welding procedure specification (wps) for saw, smaw, gmaw, gtaw, fcaw.

This document specifies requirements for the content of welding procedure specifications for arc welding processes. These settings are not visible to the welder with the hood down As per manufacturing drawing ( groove / fillet) root spacing :

Welding procedure specification template Fill out & sign online DocHub

14 Welding Procedure Specification Variables WELDING ANSWERS

Joints, base metals, filler metals, positions, preheat, pwht, gas etc. You are required to obtain and maintain a library of welding procedures and corresponding welder qualifications. Web sample welding procedure specification (wps) for saw, smaw, gmaw, gtaw, fcaw. It provides instructions on how to perform a specific welding process, including information about the materials, equipment, and parameters to be used. Details of the iso 15609 series are given in iso 15607.

Web 62 comments / welding procedure specification (wps) / by sandeep anand. Part 1 arc and gas welding of steels and arc welding of nickel and nickel alloys. Details of the iso 15609 series are given in iso 15607.

These Settings Are Not Visible To The Welder With The Hood Down

Web welding procedure specification is a vital document in wps welding operations that outlines the specific welding procedures to be followed for a particular welding job. Arc welding of aluminium and its alloys; Sample wps qualification test record for electroslag and electrogas welding form. Manual joints (qw 402) joint design :

Welding Is Considered A Special Process In The Terminology Of Standards For Quality Systems.

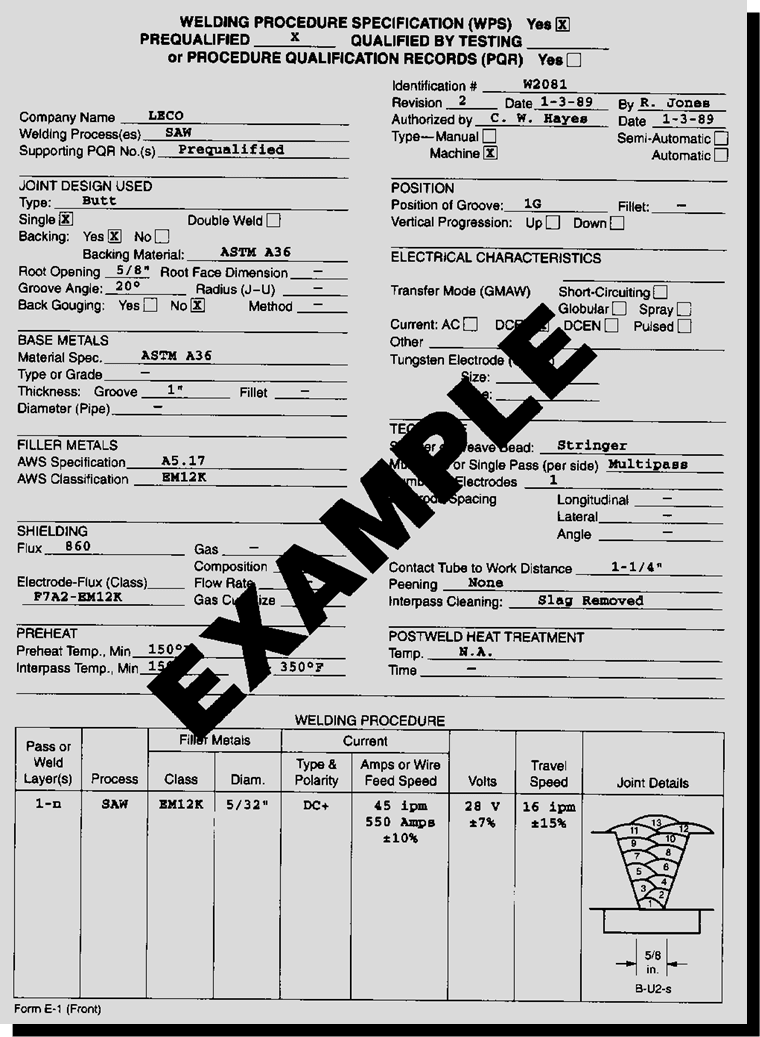

Web annex n aws d1.1/d1.1m:2010 354 welding procedure specification (wps) yes prequalified _____ qualified by testing _____ or procedure qualification records (pqr) yes You are required to obtain and maintain a library of welding procedures and corresponding welder qualifications. Details of the iso 15609 series are given in iso 15607. Web sample welding procedure specification (wps) for saw, smaw, gmaw, gtaw, fcaw.

Web This Specification Provides The Requirements For Qualification Of Welding Procedure Specifications, Welders, And Welding Operators For Manual, Semiautomatic, Mechanized, And Automatic Welding.

Pass process filler metal current (asme sec iic) heat input (kj/mm) Electrode size current type & polarity amperage. It provides instructions on how to perform a specific welding process, including information about the materials, equipment, and parameters to be used. Web welding procedure specification examples and templates can be found in annex n of aws d1.1 or annex o of aws d1.5.

A Welding Procedure Specification (Wps) Is A Written Document Providing Direction To The Welder (Or Welding Operator).

The welding processes included are electrogas welding, electron beam welding, electroslag welding, flux cored arc welding, gas metal arc welding, gas. The first step is to obtain weld procedure qualification records (wpqr). Web 62 comments / welding procedure specification (wps) / by sandeep anand. Web (excerpt from aws b2.1/b2.1m:2021) the american welding society, acting under ansi rules for consensus standards, publishes aws standard welding procedure specifications (swpss) which are initiated by the b2g subcommittee on procedure qualification records.

These settings are not visible to the welder with the hood down Pass process filler metal current (asme sec iic) heat input (kj/mm) ** as per quality specs and documents ( qcp ) prepared by: Part 1 arc and gas welding of steels and arc welding of nickel and nickel alloys. The wps serves as a guide for welders, supervisors, inspectors, and quality control personnel in ensuring that welding is performed consistently and to the required standard.